ELECTRIC ARC FURNACE AC The Raw Materials

2025.8.5

1. INTRODUCTION

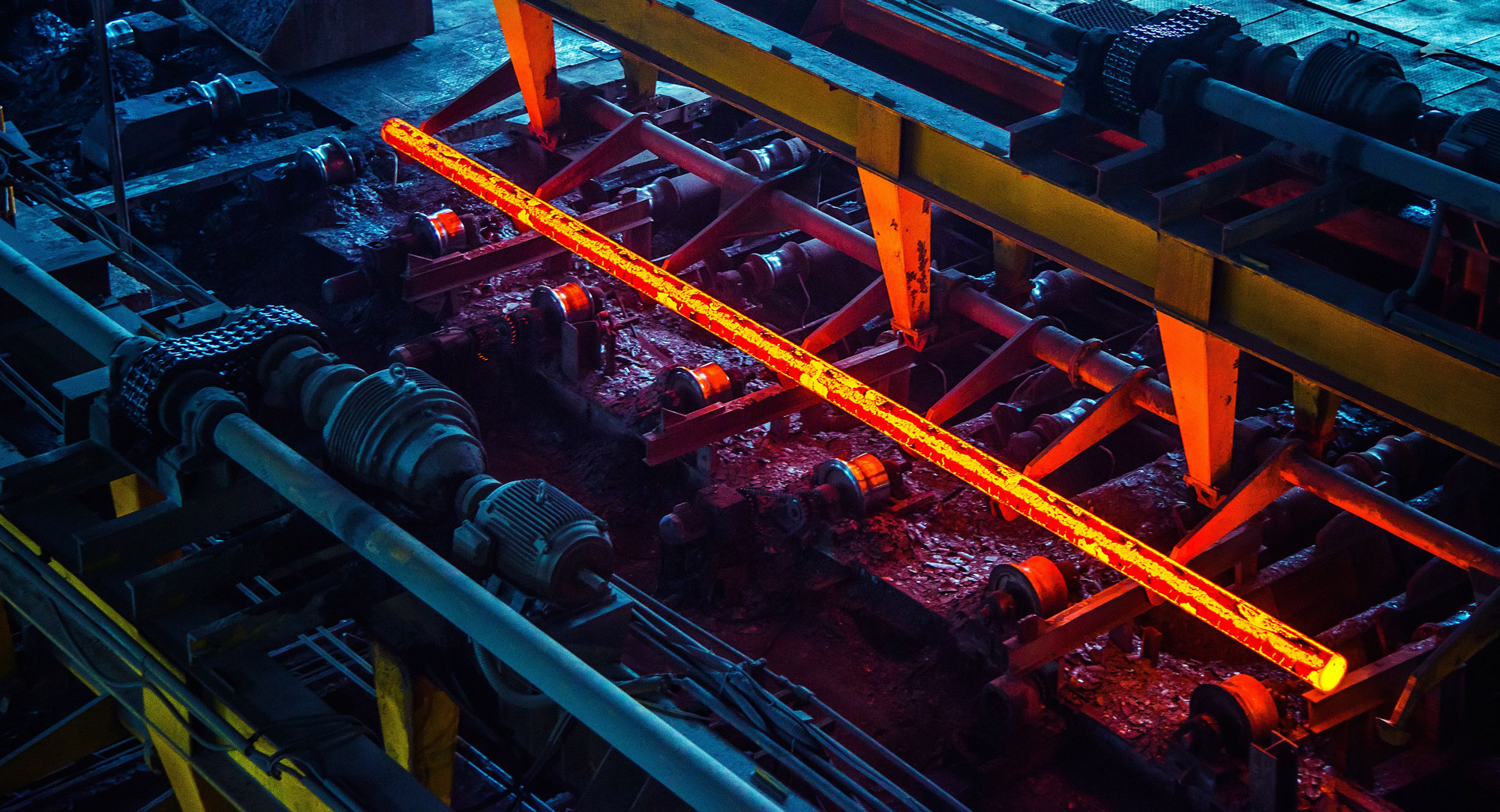

Through this report we are going to explain in details the most common raw materials used in the Electric Arc Furnace (AC) based on the latest available technologies. The charging of the raw materials is the primary step of the Electric Steelmaking routes as shown here below:

The charging of the raw materials into the EAF has done through the using of a proper bucket (or basket) which is a simple metal vessel that has an opening mechanism on the bottom part. Normally more than one bucket has to be loaded to allow the complete charging of the furnace. On the other hand some types of raw material can be charged using an automatic continuous feeding system.

2. RAW MATERIAL TYPES

Raw material may be up to 100% scrap or various mixes of hot metal, pig iron, DRI (hot and/or cold) and HBI.

Worldwide, scrap covers around 75% of the raw materials for EAF, while DRI and HBI covers around 15% and the balance (10%) is covered by pig iron and hot metal.

2.1 SCRAP

Scrap is the mostly used raw materials for the EAF charge. It classification depends on the grades of steel manufactured and the sorts of charge scrap available commercially in the market. The following properties should be entailed for the sake of the scrap material classifications:

- DENSITY Scrap density varies between light scrap (normally less than 0.5 t/m3) to heavy scrap (up to 1 t/m3). The ideal avg. scrap density should be around 0.7 t/m3; Light scrap could be melted easily but require more number of buckets while heavy scrap require more energy and can lead an increasing of refractory and graphite electrodes consumption during the melting stage;

- GEOMETRY The knowledge of the scrap material geometry enables optimum filling of the EAF charge baskets. The maximum size of the pieces should be around 150 x 50 x 50 cm;

- QUALITY it depends from the presence of harmful / undesirable elements and other factors such as the yield. Elements that can affect the quality of scrap mainly include sulphur, phosphorus, copper e zinc;

Here below it shown a typical chemistry of the most common kind of scrap available in the market:

2.2 DIRECT REDUCED IRON (DRI)

Direct Reduced Iron (DRI) is the product of the direct reduction of iron ore in the solid state by carbon monoxide and hydrogen derived from natural gas or coal. During direct reduction, oxygen is removed from iron ore reducing it to metallic iron and the more stable oxide such as Silica (SiO2), Alumina (Al2O3), Lime (CaO), Magnesia (MgO) and phosphorous (P).

Most gas-based direct reduction plants are part of integrated steel mini-mills, located adjacent to the electric arc furnace (EAF) steel plant.

DRI can be either hot or cold charged to the EAF. Some steel companies ship DRI from their captive direct reduction plants to their remote steel mills and a small volume of DRI is sold to third parties. There are many small rotary kiln furnaces producing DRI, known as sponge iron, using coal as energy and reductant source. Some of the sponge iron plants are captive to steel mills.

The characteristics of DRI should be summarizes as below:

METALLIZATION Metallization is the ratio of Metallic Iron compared to the Total Iron, including FeO). It could be from about 85% to around 95%, depending on the reduction process used. So metallization is a measure of efficiency of direct reduction;

CHEMICAL COMPOSITION The reduction process removes most of the oxygen and sulfur from the iron ore, but leaves some impurities and gangue content. Gangue consists of both acidic and basic elements. Basic elements include MgO and CaO and acidic components include Si, Al and TiO2. DRI doesn’t contain tramp elements, just some traces of sulfur and phosphorus;

CARBON CONTENT

METALLIZATION Metallization is the ratio of Metallic Iron compared to the Total Iron, including FeO). It could be from about 85% to around 95%, depending on the reduction process used. So metallization is a measure of efficiency of direct reduction;

Different processes economically achieve different upper limits of metallization. The table below represents some direct iron composition produced by processes using different reductant and feed materials:

2.3 HOT BRIQUETTED IRON (HBI)

Hot Briquetted Iron (HBI) is a premium form of DRI that has been compacted at a temperature greater than 650° C at time of compaction.

HBI is compact and the briquettes are easy to feed into the furnace. In contrast, scrap is most unwieldy and sometimes needs cutting down, an expensive process.

Also for HBI we’ve to consider the parameters indicated for DRI such as chemical composition, carbon and gangue contents and metallization.

2.4 PIG IRON

The average use of pig iron into EAF is about 5% of the total charging. Usually a maximum of 15-20% of cold pig iron is used because it need a longer time to be melt compared to the metal scrap. Pig iron is another group of materials in which the chemical composition can vary quite considerable as shown in the table here below:

2.5 HOT METAL

Hot metal production is a standard part of operations in integrated steel mills. hot metal is produced in the blast furnace (BF) from iron ore pellets. This hot metal is then refined into the basic oxygen furnace (BOF) in order to produce steel. Some operations charge hot metal to the EAF by swinging the roof and pouring it into the furnace. An alternative method of charging the hot metal is to pour it down a launder which is inserted into the side of the EAF.

3. RAW MATERIAL PROPERTIES

Here below we can indicate the main properties of the raw materials (listed above) involved in the charging of the EAF:

4. ADVANTAGES / DISADVANTAGES OF THE RAW MATERIALS

Many factors can determine the using of one or another raw materials. In general the availability and cost of the raw materials (generally based on geographical area) will determine the charge composition of the EAF.

Anyhow, we can summarize the advantages and disadvantages of the different raw materials in the table here below:

With the next article we’re going to explain in details the charging phase of an EAF.