Introduction to Graphite Electrodes

2025.8.22

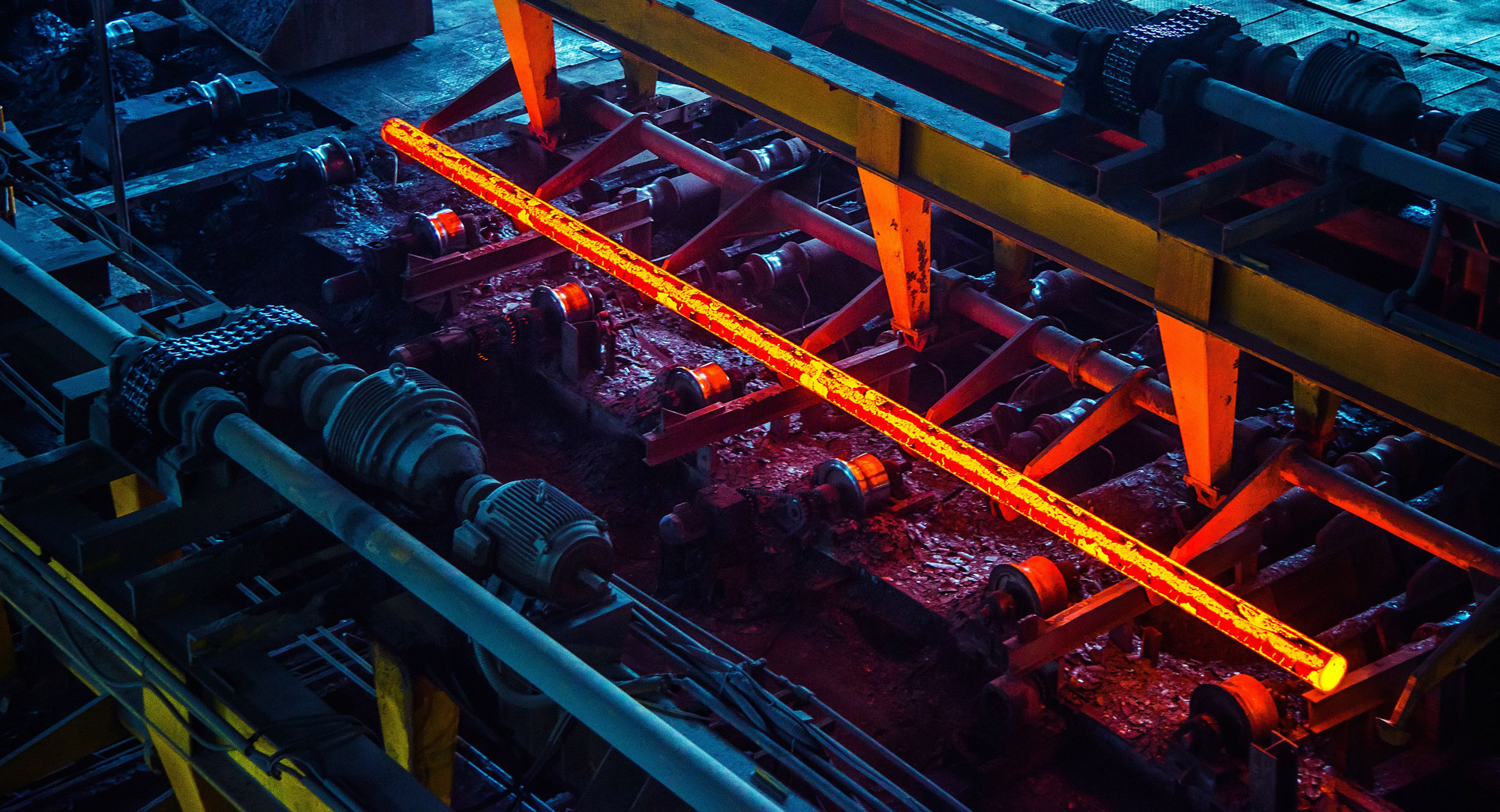

Graphite electrodes are cylindrical rods made of graphite, a form of carbon, used primarily in electric arc furnaces (EAF) for steelmaking. They conduct electricity to generate the high temperatures needed to melt scrap metal and other materials in the EAF. JISteel electrodes are essential for recycling steel and producing various metal alloys.

Here’s a more detailed explanation:

Key Properties and Characteristics:

1.High Electrical Conductivity:

Graphite is an excellent conductor of electricity, making it ideal for carrying the large currents needed in EAFs.

2.High Temperature Resistance:

Graphite electrodes can withstand extremely high temperatures (up to 3,000°C or higher) without melting or degrading significantly.

3.Mechanical Strength:

Graphite electrodes possess sufficient mechanical strength to withstand the stresses and vibrations within the furnace environment.

4.Low Electrical Resistance:

This property ensures that the electricity flows efficiently through the electrode, minimizing energy loss.

5.Thermal Conductivity:

Graphite’s high thermal conductivity helps to distribute heat effectively within the furnace.

Production Process:

Graphite electrodes are manufactured through a complex process that includes:

1.Raw Material Selection: Petroleum coke or needle coke are typically used as the primary raw material.

2.Calcining: The coke is heated to remove volatile matter.

3.Mixing: The calcined coke is mixed with a binder material, often pitch.

4.Forming: The mixture is shaped into cylindrical electrodes.

5.Baking: The electrodes are baked at high temperatures to harden and strengthen them.

6.Graphitization: Finally, the electrodes undergo a graphitization process, where they are heated to extremely high temperatures (around 3,000°C) to convert the carbon to graphite.

Applications:

1.Steelmaking:

Graphite electrodes are crucial for the production of steel in electric arc furnaces, particularly for recycling steel scrap.

2.Ferroalloy Production:

They are also used in the production of various ferroalloys.

3.Smelting:

Graphite electrodes are used in other smelting processes where high temperatures are required.

4.Other Industries:

Graphite rods, a form of graphite electrodes, are also used in fiber optics, semiconductor applications, and even in fishing rods due to their sensitivity and durability.