Graphite Electrodes: A Core Material in Electric Arc Furnace Steelmaking – Process & Market Outlook

2025.7.25

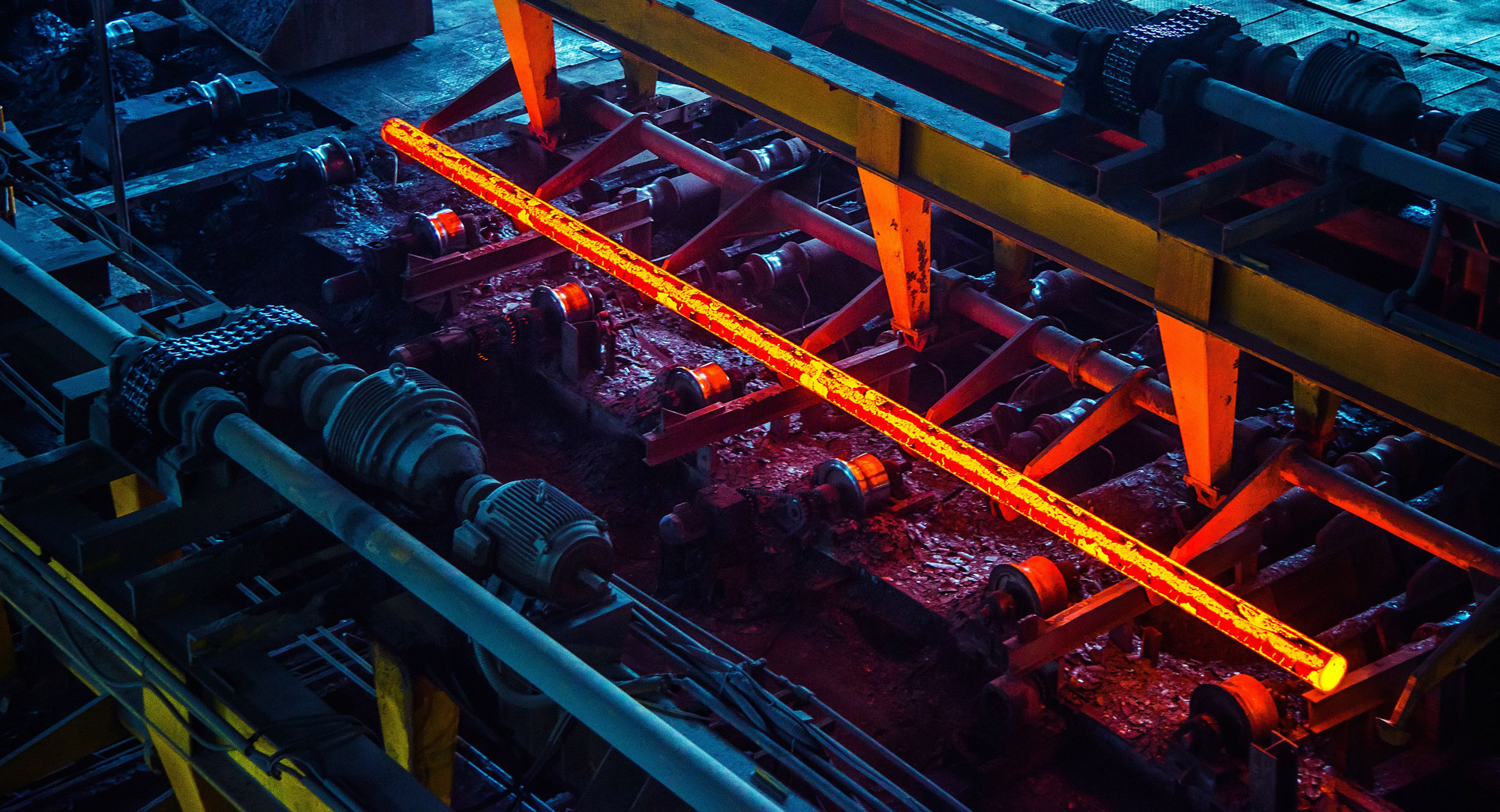

With the global steel industry moving rapidly toward electric arc furnace (EAF) steelmaking, graphite electrodes are playing an increasingly vital role. Acting as the “energy bridge” in EAF operations, they are key to improving efficiency, reducing costs, and achieving green, low-carbon steel production.

🏭 Manufacturing Process: A Complex and Precise Journey

Graphite electrodes have a long production cycle and require highly controlled processes, including:

- Raw Material Selection

Premium petroleum coke and needle coke are selected as base materials, with coal tar pitch as the binder. Impurities such as ash, sulfur, and volatile content are strictly controlled. - Mixing and Kneading

Precisely weighed raw materials are mixed and kneaded at high temperatures to form a homogeneous, plastic mass. - Forming

The mixture is shaped by extrusion (or isostatic pressing) to achieve the required density and dimensional precision. - Baking

The formed green electrodes are baked in tunnel kilns at around 1200°C to carbonize the coke and develop initial strength. - Impregnation and Re-Baking

To improve bulk density and mechanical strength, baked electrodes undergo pitch impregnation followed by a second baking cycle. - Graphitization

Electrodes are treated in high-temperature graphitization furnaces (up to 3000°C) to convert non-graphitic carbon into a graphitic structure, enhancing conductivity. - Machining

Final processing includes turning, end-face finishing, and threading for nipple connections. - Quality Inspection & Packaging

Each electrode undergoes rigorous testing for resistivity, density, strength, and dimensional accuracy to ensure consistency and performance.

⚙️ Key Technical Features

- Low Electrical Resistivity – for efficient current flow and minimal energy loss

- High Bulk Density – improves oxidation resistance and thermal shock performance

- Superior Mechanical Strength – withstands high temperatures and electrical impacts

- Precision Threading & Nipple Fit – reduces contact resistance and improves operational reliability

🌍 Market Outlook: EAF Expansion Drives Global Demand for Graphite Electrodes

The growing shift to “short process” steelmaking and decarbonization goals is accelerating EAF adoption globally. Industry insights show:

Supply & Price Trends: Despite raw material price fluctuations, high-quality graphite electrodes remain in structural shortage, making them a strategic long-term material.

China: With new EAF capacity under construction, demand is shifting toward high-power (HP) and ultra-high-power (UHP) electrodes.

Emerging Markets: Countries in the Middle East, India, and Southeast Asia are rapidly developing EAF projects, generating new demand for premium electrodes.

Supply & Price Trends: Despite raw material price fluctuations, high-quality graphite electrodes remain in structural shortage, making them a strategic long-term material.

JISTEEL’s Product & Service Strengths

JISTEEL offers a full range of HP and UHP graphite electrodes in various sizes and specifications. Our advantages include:

- Use of premium needle coke raw materials

- Full-process quality control and traceability

- Matching nipples and precision threading

- Technical support for electrode selection and application

With years of experience serving global metallurgical clients, JISTEEL is committed to improving product consistency, optimizing delivery, and ensuring stable supply of this vital material for high-temperature furnace operations.