Innovations and Developments in Steel Continuous Casting

2025.6.19

Technology: The Key to Enhancing Efficiency and Quality in the Iron and Steel Industry

Overview of Continuous Casting Technology and Its Core Role in Steel Production

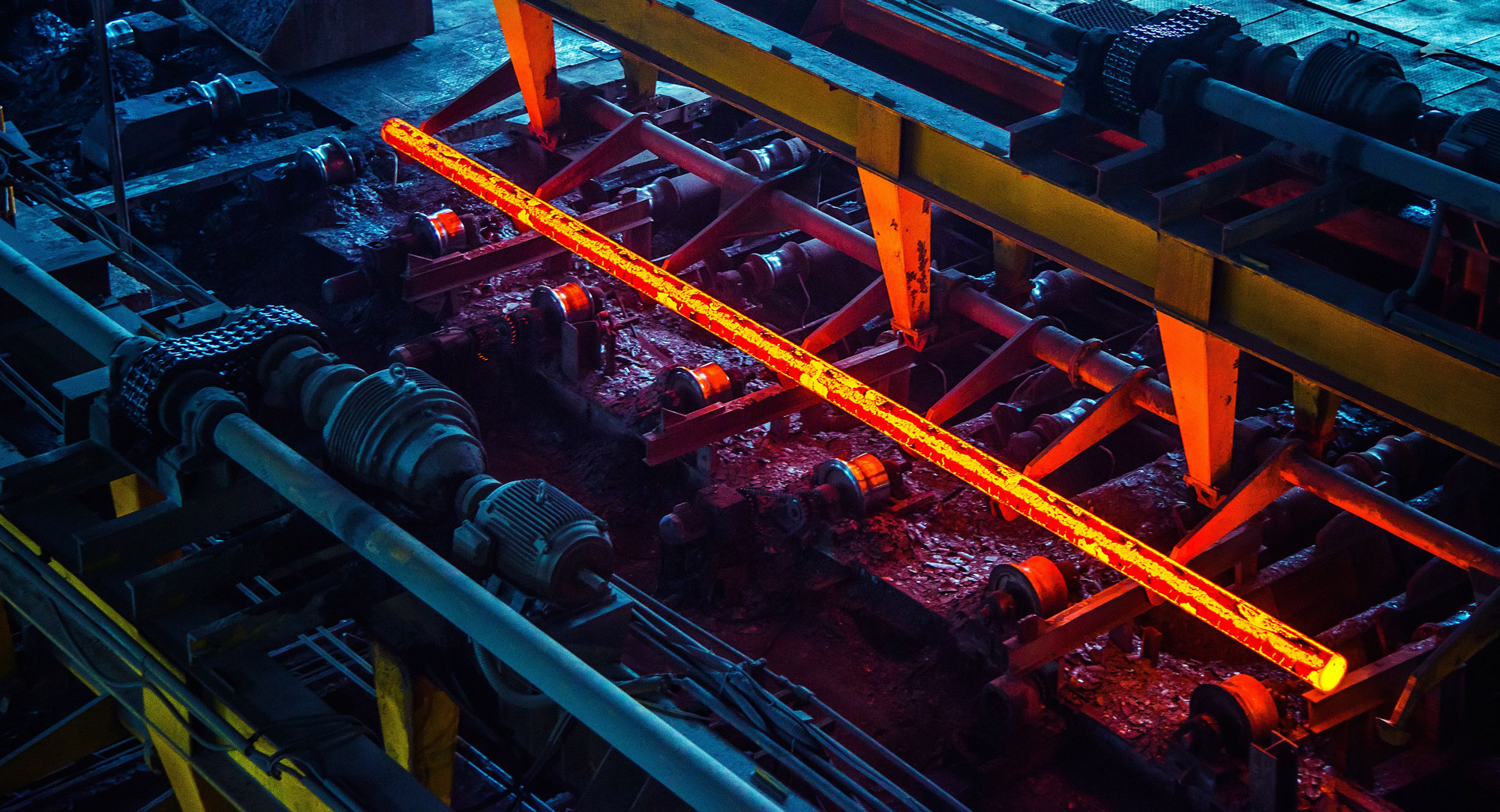

Continuous casting technology (CC), as a critical link in modern steel production processes, has become an essential bridge connecting steelmaking and rolling operations. Since its industrial application in the 1950s, this technology has undergone continuous innovation and development over half a century, fundamentally transforming the traditional ingot casting-blooming process model. The basic principle of continuous casting involves pouring refined molten steel into a water-cooled mold through a tundish, where the steel rapidly solidifies to form a solidified shell with a specific shape. The strand then undergoes further solidification in the secondary cooling zone before being cut to the required length by cutting equipment.

Compared to traditional ingot casting, continuous casting offers significant advantages: metal yield increases by 10%-15%, energy consumption decreases by 25%-30%, production efficiency improves by 30%-50%, and working conditions and environmental friendliness are greatly enhanced. According to the World Steel Association, approximately 96% of global crude steel production in 2022 utilized continuous casting, with this proportion exceeding 98% in China, fully demonstrating the central role of continuous casting technology in modern steel production.

Main Types and Process Characteristics of Modern Continuous Casting Technology

Conventional Slab Continuous Casting Technology

Slab continuous casting primarily produces rectangular cross-section strands with thicknesses of 150-300mm and widths of 1000-2500mm, serving as raw material for hot-rolled plates. Modern slab casters typically adopt straight-arc or full-arc designs, equipped with advanced technologies such as hydraulic oscillation devices, dynamic soft reduction, and dynamic secondary cooling control. The main technical challenges in slab casting include preventing surface longitudinal cracks, center segregation, and internal cracks. In recent years, significant improvements in slab quality have been achieved through optimized mold taper design, the development of new mold fluxes, and the application of electromagnetic braking technology.

Billet and Bloom Continuous Casting Technology

Billets (120-450mm square) and blooms (width-to-thickness ratio generally less than 3) are mainly used to produce long products such as rebars, wire rods, and sections. These casters usually feature multi-strand designs (4-8 strands) to enhance production efficiency. Technological advancements in billet casting are reflected in high-speed casting (up to 5m/min), efficient secondary cooling systems, and breakout prediction systems. Notably, breakthroughs in high-efficiency production have been achieved in recent years through optimized mold copper tube design and improved secondary cooling water distribution models, increasing the operational efficiency of billet casters to over 90%.

Beam Blank and Thin Slab Continuous Casting Technology

Beam blank casting enables near-net-shape casting of sections (e.g., H-beam blanks), significantly reducing subsequent rolling processes and energy consumption. Thin slab casting (50-90mm thickness) is the core of Compact Strip Production (CSP) technology, offering energy savings of 30%-40% compared to traditional processes. Thin slab casting and rolling technology has become a highly efficient route for producing hot-rolled strips, with global capacity exceeding 100 million tons annually. Recent developments include optimized funnel-shaped mold designs, liquid core reduction technology, and quality control under high casting speeds.

Key Innovation Areas in Continuous Casting Technology

High-Speed Continuous Casting Technology

Increasing casting speed is a direct way to enhance caster productivity but also introduces technical challenges. When speeds exceed critical values, issues such as severe mold level fluctuations, poor mold flux lubrication, and uneven shell growth arise. To address these challenges, modern high-speed casting technologies employ innovative solutions: developing low-viscosity, high-crystallization-temperature mold fluxes, optimizing mold taper designs, applying electromagnetic braking to control steel flow, and improving nozzle arrangement and cooling intensity in the secondary cooling zone. Currently, conventional slab casting speeds have increased from 1.0m/min in early stages to 1.8-2.2m/min, while billet casting speeds can reach 4-5m/min.

Dynamic Soft Reduction and Liquid Core Control Technology

Dynamic soft reduction technology applies controlled reduction at the solidification end to compensate for shrinkage, significantly improving center segregation and porosity. Modern casters are typically equipped with segmented hydraulic reduction systems that adjust reduction positions and amounts in real time based on steel grade, section, and process parameters. Compared to static soft reduction, dynamic soft reduction more accurately tracks the “mushy zone,” improving reduction efficiency by over 30%. Liquid core control technology optimizes solidification structures through electromagnetic stirring and final-stage intensive cooling, reducing segregation and inclusion aggregation. Practical results show that combining electromagnetic stirring with dynamic soft reduction can reduce the center segregation index of high-carbon steel by more than 50%.

Intelligent Control Systems and Digital Technology Applications

With the advancement of Industry 4.0, intelligent control of continuous casting has become a key development direction. Modern casting control systems have evolved from traditional PID regulation to intelligent control based on multi-parameter coupling models, reflected in several aspects: machine vision for real-time monitoring of mold level fluctuations and strand surface quality; breakout prediction systems based on big data analysis, forecasting sticker breakouts 30-60 seconds in advance; intelligent secondary cooling water distribution dynamically adjusting cooling intensity based on steel grade, casting speed, and surface temperature; and digital twin technology creating virtual casters for process optimization and fault diagnosis. One steel plant reported a 40% reduction in surface defects and an 80% decrease in breakout incidents after implementing intelligent control systems.

Challenges and Future Trends in Continuous Casting Technology

Technical Bottlenecks in High-Quality Steel Casting

Although continuous casting is well-established, challenges remain in producing certain high-quality specialty steels. For example, ultra-pure stainless steels are prone to surface micro-cracks; high-carbon steels exhibit severe center segregation tendencies; and silicon steels require strict control of columnar-to-equiaxed grain ratios. Solutions include developing specialized mold fluxes, optimizing electromagnetic stirring parameters, and controlling cooling paths. Recent research shows that pulsed electromagnetic field-assisted casting can effectively refine solidification structures in high-alloy steels, increasing equiaxed grain ratios by 20%-30%.

Development of Green and Low-Carbon Continuous Casting Technologies

Under carbon neutrality goals, energy-saving and emission reduction in continuous casting have become focal points. Key directions include waste heat recovery (e.g., secondary cooling steam recovery), low-energy electromagnetic stirring, and high-efficiency mold copper plate development. Additionally, scrap utilization in casting is critical for emission reduction. Optimizing tundish metallurgy and filtration technology can increase scrap ratios without compromising steel cleanliness. One company’s “green casting” system reduced process energy consumption by 15% and CO2 emissions by 12%.

Future Technology Outlook

Looking ahead, continuous casting will evolve toward “high efficiency, intelligence, sustainability, and precision.” Specific trends include expanding near-net-shape casting (e.g., direct strip casting), deeper AI integration in process control, full-process digitalization through new sensors and IoT, and next-generation casting processes for high-alloy and high-strength steels. Notably, digital twin-based intelligent casting systems will become a competitive focus, potentially boosting productivity by 20%-30% and reducing quality losses by over 50%.

As a critical link in modern steel production, continuous innovation in continuous casting technology is vital for enhancing the overall competitiveness of the steel industry. China’s continuous casting technology has progressed from following to leading in areas such as high-efficiency casting and intelligent control. Moving forward, steel enterprises should increase R&D investment, particularly in intelligent transformation, precision quality control, and green technologies, to provide robust technical support for high-quality industry development. Through continuous advancements, the steel industry will better address resource, energy, and environmental constraints, achieving more efficient, cleaner, and sustainable growth.