DC electric arc furnace: a new era for the steelmaking industry

2025.5.8

Development trend of DC electric arc furnace

[History and current situation]

For a long time, steelmaking electric arc furnaces have mainly adopted AC three-phase design. However, this AC electric arc furnace has many limitations that are difficult to overcome. In the 1970s and 1980s, industrially developed countries began to explore and gradually promote DC electric arc furnaces (DCEAF), and made significant progress. Although Japan started late in the research and development of DC electric arc furnaces, it has developed rapidly and has become the country with the most DC electric arc furnaces in the world. In recent years, with the rise of large-capacity single electric arc furnaces, the steelmaking industry has shown a new development trend to meet the steel mills’ pursuit of higher production efficiency.

In addition, the advancement and application of high-power thyristor technology have once again attracted attention to the advantages of DC electric arc furnaces.

[Technology Innovation and Application]

Recently, Italy successfully manufactured the world’s largest 420-ton DC electric arc furnace, as well as a matching 420-ton ladle refining furnace and double vacuum degassing system. The equipment mainly produces low-carbon steel, ultra-low-carbon steel and high-grade deoxidized and killed steel, with an annual output of up to 2.6 million tons. At the same time, Tokyo Steel’s Tahara Plant also put into operation the first ultra-high-power double-graphite top electrode DC electric arc furnace in June 2010. The furnace type is designed to have a production rate of 360t/h, which is not only efficient but also has low operating costs. This series of innovations and changes reflects the urgent need of the steelmaking industry to improve production efficiency and ensure high quality of steel.

Characteristics and advantages of DC electric arc furnace

[ Mechanical equipment and power supply system ]

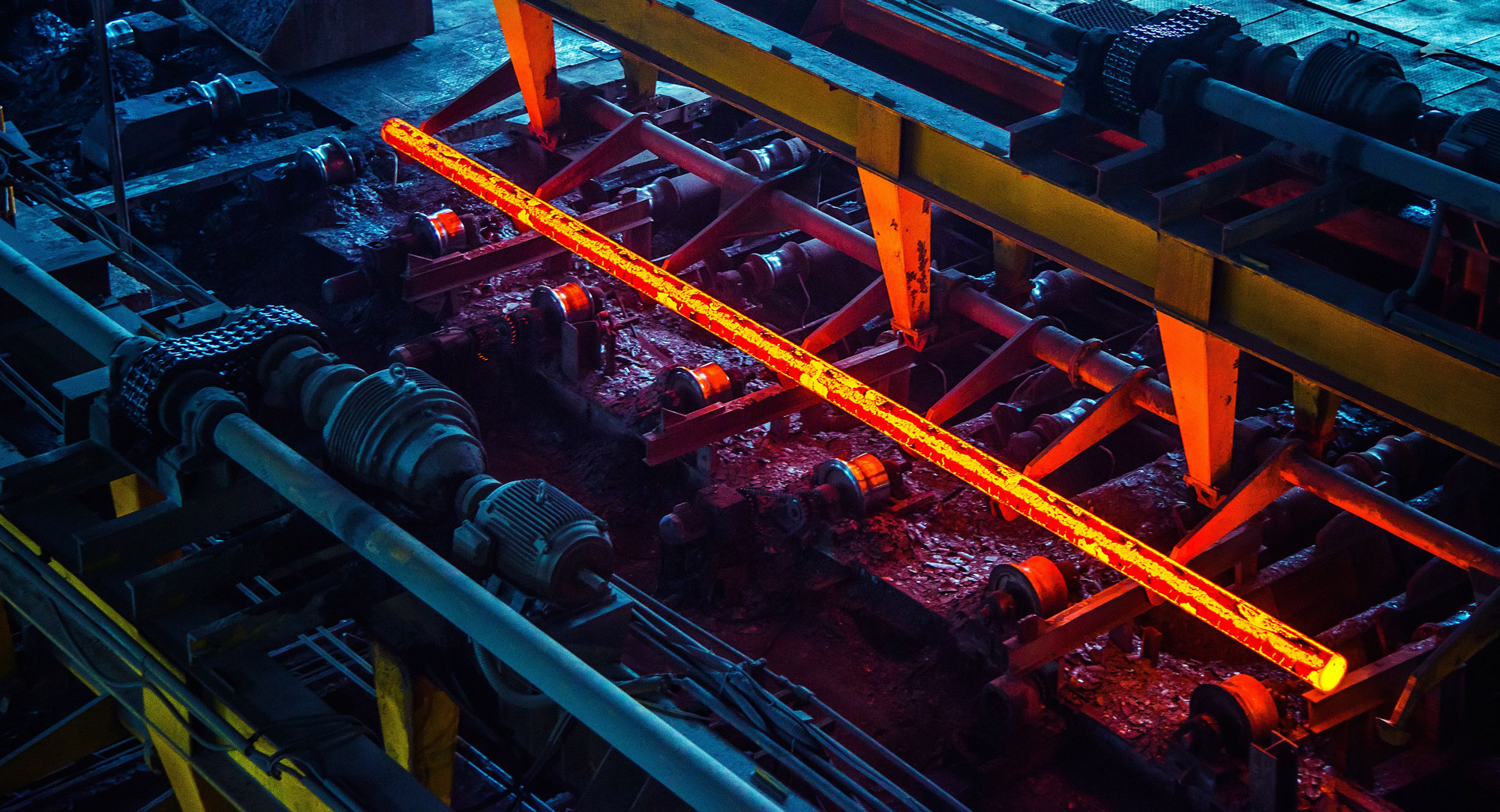

The mechanical equipment of the DC electric arc furnace covers multiple components such as the furnace body, furnace cover and its lifting and rotating mechanism, electrodes and their lifting mechanism, and is also equipped with rectifiers and reactors, thus forming a unique power supply system. Its current circuit is realized through the power connection point of the furnace bottom device, but the maintenance and life of the power connection point have become key challenges in operation. To address this problem, copper plates are usually laid on the steel plate at the bottom of the furnace to optimize the conductivity, and three layers of magnesia carbon bricks are built on it, and then covered with refractory materials.

[Comparison with AC arc furnace]

Compared with AC arc furnace, this DC arc furnace has many advantages. First, its power supply system is more efficient, and the application of thyristor technology solves the manufacturing technology problems of high-power DC power supply equipment. Secondly, the double graphite electrode technology provides higher power output and smaller electrode diameter, thereby reducing grid interference. In addition, the DC arc furnace also eliminates the influence of electromagnetic induction, so that the loss on the secondary conductor is only the DC resistance loss, and the mechanical structure is simpler. At the same time, the stable arc and random electromagnetic force rotation also make the arc more concentrated and stable.

Application examples of DC arc furnace

[Practical experience of Tokyo Steel]

At Tokyo Steel’s Tahara Plant, this DC arc furnace is widely used in the production of medium carbon steel, low carbon steel and ultra-low carbon steel. The furnace is designed as a full-platform, split-shell furnace, and incorporates the continuous scrap steel feeding Consteel and dual graphite electrode DC technology. In addition, the DC arc furnace is equipped with an advanced power supply system, including core components such as transformers and thyristors, as well as auxiliary equipment such as DC reactors. In practice, Tokyo Steel has demonstrated the advantages of DC arc furnaces in terms of non-interference to the power grid and stable process.

【Automation control system】

The automation system of the DC arc furnace is based on the most advanced software and hardware platform, including two levels of equipment control and process control. Its electrode control program software package and hydraulic system design ensure extremely fast response time and enhanced average melting power. Improvements in online monitoring of process data and recording functions further optimize arc performance, which is critical for ultra-high power arc furnaces. The system can fully control all electrical and chemical energy parameters and automatically adjust the working point according to different process stages, thereby ensuring the quality of steel and the effective use of energy.

The intelligent control system of the DC arc furnace ensures efficient and safe operation, reduces manual intervention, and improves production efficiency. At the same time, the requirements for high productivity are met, as auxiliary work time is minimized. This is due to the installation of a reliable mechatronic system, which not only improves operator safety by avoiding direct exposure to the dangers of the arc furnace, but also allows remote control from the main control room.