Global Metallurgy Industry Embraces Sustainable Innovation and Strategic Collaborations in 2025

2025.5.14

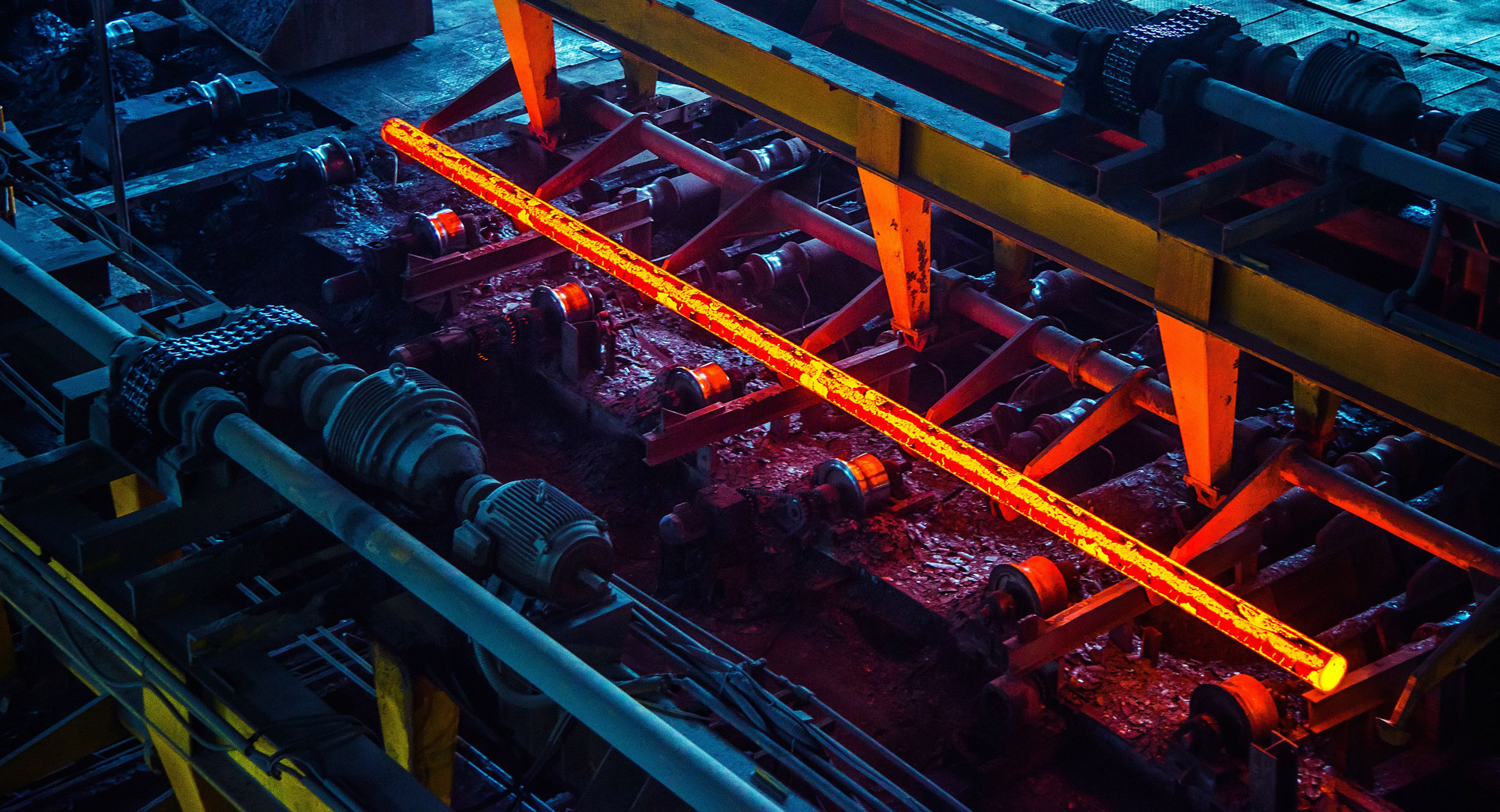

The global metallurgy sector is undergoing a significant transformation in 2025, driven by the imperative for sustainable practices, technological advancements, and strategic partnerships.

Advancements in Sustainable Mining Practices

In India, the Mining, Geological and Metallurgical Institute of India (MGMI) recently hosted the ‘Prism 2025’ seminar in Nagpur, focusing on ‘Progressive Resource Innovation for Sustainable Mining’. The event emphasized the importance of research, development, and collaboration in advancing the mining, geology, and metallurgy sectors.

Strategic Partnerships for Decarbonization

Chinese steelmaker HBIS Group has signed a Memorandum of Understanding with Vale, a major iron ore mining company, to collaboratively work towards decarbonizing the steel value chain. The partnership aims to explore the use of the Tecnored furnace to manage solid waste and extract valuable metals, and to investigate groundbreaking decarbonization technologies such as hydrogen metallurgy and carbon capture, utilization, and storage (CCUS).

Innovations in Low-Carbon Iron Production

In Australia, BHP and Rio Tinto are collaborating to construct a pilot plant in Western Australia to produce low-carbon iron using Pilbara ores. This initiative will utilize renewable power and direct reduced iron technology in an electric smelting furnace, aiming to significantly reduce greenhouse gas emissions for steelmakers using Australian iron ore.

Challenges in the Copper Smelting Sector

The global copper smelting sector is facing challenges due to a dramatic decrease in conversion fees, resulting from rapid global smelter capacity expansion, especially in China. Despite attempts to curb output to stabilize fees, competition for raw materials remains fierce, posing significant survival challenges for smelters as feed competition and input sources tighten.

The metallurgy industry in 2025 is characterized by a concerted effort to embrace sustainable practices, technological innovation, and strategic collaborations. While challenges persist, particularly in sectors like copper smelting, the industry’s commitment to transformation signals a promising trajectory towards a more sustainable and efficient future.